Custom Furniture for ANNND Coffee (86㎡, Shenzhen): A Model of Intertwined Light and Shadow & Diversified Integration of Retro and Modern Styles

[Project File]

- Project Name: ANNND Coffee

- Completion Time: July 2023

- Project Location: Shenzhen, China

- Style Positioning: Modern Casual Style (Integrating Coffee Culture and Living Aesthetics)

- Space Type: Comprehensive Café (Including Coffee, Dessert, Brunch and Beverage Experience Zones)

- Space Area: 86㎡

- Service Offering: Turnkey Furniture Customization (Material Fusion Design, Light & Shadow Adaptation, Layout Dimension Adjustment, Structural Detail Optimization)

- Core Materials: Weathered Old Elm Wood, Eco-Friendly Wood Wax Oil, Stainless Steel (Brushed Matte Finish), Custom Upholstery

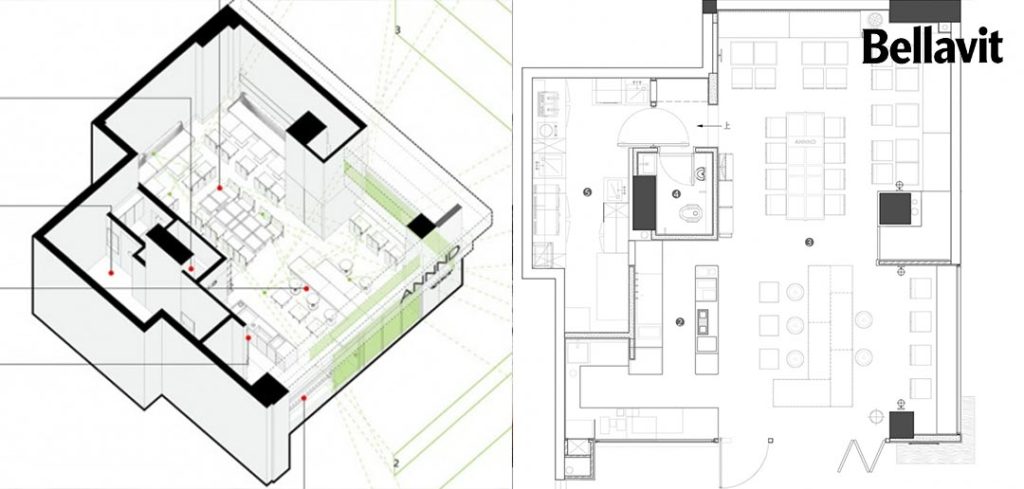

Bellavit undertook the turnkey furniture customization for ANNND Coffee, focusing on the core principles of “Precise Small-Space Adaptation, Strict Quality Control, and Diversified Style Integration”. We centered on the requirements of retro-modern material fusion, square-shaped silhouettes, light & shadow presentation, and safety & comfort. Additionally, we oversaw the entire process from demand consultation to mass delivery. Through the subtle interplay of materials and light, along with the seamless integration of diverse styles, the 86㎡ small space exudes unique charm, helping the café become a renowned social media-friendly landmark (Instagram-worthy spot) in Shenzhen.

I. Demand Consultation: Anchoring Core Objectives & Optimizing Adaptation

In the initial phase, based on the original layout of ANNND Café and its positioning of “Material Fusion + Light & Shadow Aesthetics + Diversified Integration”, we defined functional zones such as casual seating and dessert experience areas. The core requirements included creating a retro-modern fusion using old elm wood and stainless steel, adopting square-shaped furniture, implementing micro-chamfering treatments, enhancing light & shadow layers, and maximizing small-space utilization. We optimized the client’s proposal by adding an arc-shaped support to reinforce the I-beam structure of large dining tables (balancing stability and aesthetics), adjusting the booth width to 60cm and refining backrest parameters. We promptly obtained approval and finalized the submitted SU drawings.

II. Product Prototyping: Refining Details & Unifying Light, Shadow & Style

After the proposal was confirmed, we entered the prototyping phase, aiming to materialize the requirements of material fusion and square shapes while ensuring natural texture and durability. We locked in the core material combination of “Weathered Old Elm Wood + Brushed Matte Stainless Steel + Light Gray Upholstery” and completed 1:1 prototyping using eco-friendly wood wax oil technology: Scattered seating tables and chairs were tailored to the space dimensions and lighting conditions; the old elm wood tabletops capture light and shadow to enhance spatial depth; stainless steel accents amplify the retro-modern fusion; 2mm micro-chamfers at contact points ensure safety and comfort; the wood wax oil finish improves moisture resistance and wear durability. Multi-person long tables retained the square silhouette, with embedded stainless steel decorative strips and brand logos, and thickened table legs for enhanced stability. After refining details based on light & shadow effects at different times, we finalized unified production standards.

III. Mass Production & Delivery: Strict Quality Control & On-Time Implementation

Following prototype confirmation, the project proceeded to mass production. Addressing the needs of diverse furniture types and small-space & light-shadow adaptation, we implemented a “Zoned Production + Full-Process Quality Control” plan to ensure both efficiency and quality. During production, we strictly controlled three core links: 1) Material Sourcing – selecting high-quality old elm wood with sufficient age, uniform weathering and rich grain (to ensure optimal light & shadow effects), manually sorting out planks with plain grain; using high-grade brushed matte stainless steel and providing environmental certification for all materials; 2) Process Control – reinforcement of old elm wood joints with mortise-tenon structures, standardizing stainless steel welding and polishing processes, and accurately implementing the wood wax oil finish and micro-chamfering treatments; 3) Shape & Light-Shadow Calibration – maintaining the square proportions of all furniture and ensuring the grain direction and installation position of each piece maximize light & shadow layers. A dedicated project group was established to update progress in real time. In July 2023, we successfully delivered and installed 30 sets of tables and chairs, 12 dining tables (including long tables) and supporting furniture on schedule, perfectly meeting the space’s requirements.

[Project Summary]

The successful delivery of the ANNND Coffee furniture customization project fully demonstrates Bellavit’s professional expertise in material fusion design, small-space adaptation, and light & shadow aesthetics. It has helped ANNND Coffee become a local renowned social media-friendly landmark. Focusing on client needs, we achieved the integration of furniture and spatial aesthetics, as well as the triple win of style, functionality and reputation through rigorous material selection, precise design and strict process control. Moving forward, Bellavit will adhere to the philosophy of “Quality as the Foundation, Service as the Core” to support more commercial spaces in creating unique, high-quality environments.