Belavit: The Gastronomic Aesthetics in the Mall, From Design Blueprint to Grand Opening

Project File

• Project Name: EASE Restaurant

• Completion Time: December 2023

• Project Location: Shenzhen, China

• Style Positioning: Warm Log Style (Nordic Minimalism)

• Restaurant Type: Chinese Restaurant

• Restaurant Area: 480㎡

• Service Content: Full-Case Furniture Customization (including adjusting layout dimensions according to renderings and optimizing product structure details)

• Core Materials: Multi-layer solid wood plywood, solid wood dining chairs, straight booths, stainless steel, lightweight private room round tables

As a professional furniture manufacturer, Belavit undertook the full-case furniture customization project for EASE Restaurant. With “precise adaptation to space needs + strict quality control” as the core, we focused on the core requirement of “simple, smart and lightweight + solid and durable structure” for furniture, followed up the entire process from demand docking, plan optimization, product sampling to mass delivery, perfectly integrating the tone of warm log style (Nordic Minimalism) with the dining atmosphere of the Chinese restaurant.

I. Demand Docking: Precisely Matching Furniture Adaptation Plan for the Space

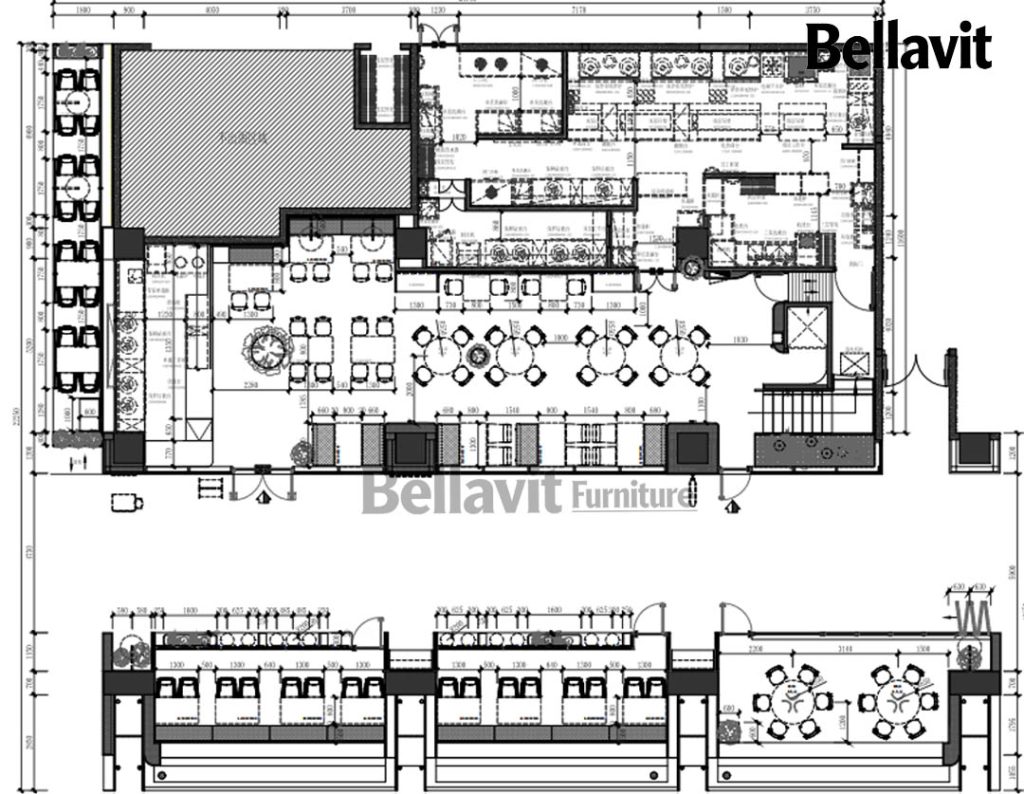

At the initial stage of the project, the customer provided the original layout drawing of the 480㎡ restaurant and the style positioning of “warm log style” (Figure 1: Original Layout Plan), clearly planning three core functional areas: scattered seats, booths and round-table private rooms. After evaluation, the original plan had the problem of cramped connection between furniture size and traffic flow, which could not give full play to the space advantages.

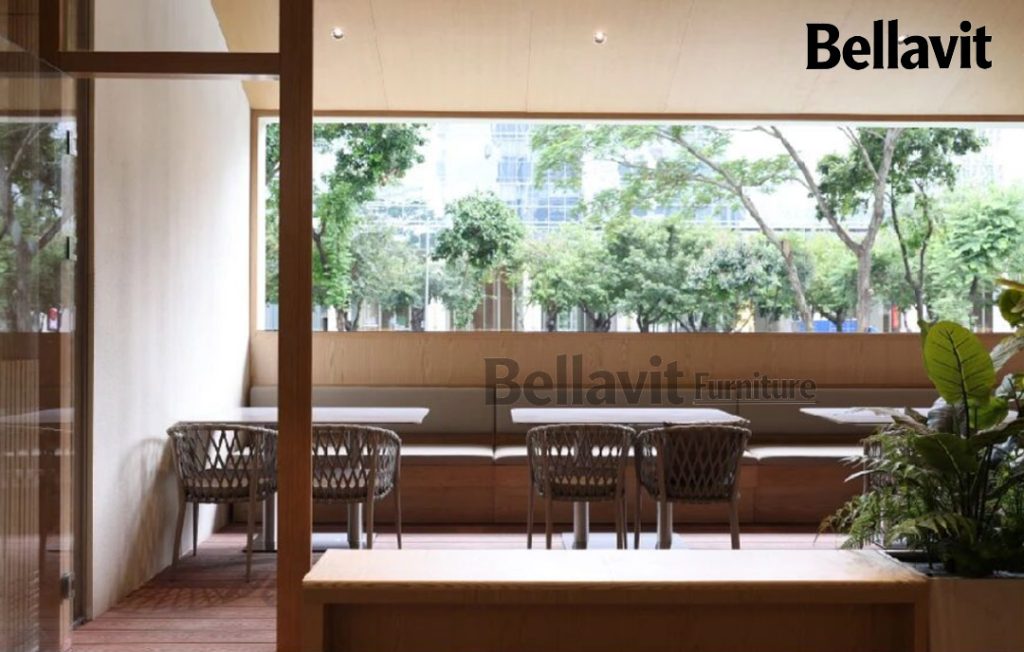

Our project team responded quickly, focusing on the core goal of “precise adaptation of furniture to space”. After in-depth communication with the customer, we put forward optimization suggestions: customize window-side booths to fit the landscape plan (Figure 2: Furniture Adaptation Optimization Diagram), widen the core passage to 1.8m to improve traffic comfort; refine the size parameters of tables and chairs in scattered seats and private rooms (Figure 3: Private Room Furniture Size Confirmation Diagram) to balance space utilization and dining experience. After 3 rounds of demand verification and size calibration, the final plan was approved by the customer, laying a solid foundation for subsequent production and manufacturing.

II. Product Sampling: Detail Calibration to Ensure Unity of Style and Practicality

After the plan was confirmed, the product sampling stage was entered. The core goal was to ensure that the custom furniture accurately fits the “warm log style” tone, and at the same time strictly implement the requirement of “simple, smart and lightweight + solid and durable structure” to meet the practicality and durability requirements of high-frequency use in the restaurant.

Based on customer needs, we locked the core material combination of “light oak logs + soft beige upholstery” and completed targeted sampling of three core products:

1. Booth Sampling: 1:1 samples were made according to the actual size of the window-side area (Figure 4: Booth Sampling Finished Product Diagram). A simple frame design was adopted to create a smart and lightweight texture, and the light oak log frame was matched with beige upholstery to fit the warm tone; at the same time, the solid and durable performance was guaranteed through reinforced structure design, and the size was optimized to meet daily dining needs.

2. Scattered Seat Table and Chair Sampling: The same series of light oak frames were used, and a simplified shape design was adopted to highlight the simple and lightweight feeling, matched with breathable linen upholstery (Figure 5: Scattered Seat Table and Chair Sampling Detail Diagram); the tabletop was treated with matte wear resistance, and the table legs adopted a reinforced structure design to balance style unity, practical easy-to-clean needs and solid durability.

3. Private Room Round Table Sampling: A 1.8m diameter solid wood round table was customized (Figure 6: Private Room Round Table Sampling Diagram). A simple cylindrical table leg and lightweight structure design were adopted to create a smart and lightweight texture to reduce space occupation; the rounded chamfer design on the edge of the tabletop improved use safety, and the solid and durable structure was guaranteed through solid wood reinforcement technology.

During the sampling stage, we invited customers to inspect the samples on-site, optimized and adjusted details such as material texture and upholstery comfort, and finally determined unified production standards to ensure the consistency and quality stability of mass-produced products.

III. Mass Production and Delivery: Strict Control to Ensure On-Time Performance

After the sampling was confirmed, the project officially entered the mass production stage. Considering the large variety and quantity of furniture required by the restaurant (including 20 sets of booths, 35 sets of scattered seat tables and chairs, 2 sets of private room round tables, etc.) and the clear opening time limit required by the customer, we formulated a special plan of “zoned production + full-process quality control” to ensure double guarantee of production efficiency and quality.

During the production process, we strictly controlled two core links to balance the “simple, smart and lightweight” texture and “solid and durable structure” performance: first, material traceability. All core materials such as light oak logs and multi-layer solid wood plywood are high-quality materials that meet environmental standards, and each batch of environmental testing reports is provided to meet the environmental requirements of the catering space; second, process control. Through mortise and tenon structure to reinforce log joints, standardized upholstery sewing process, environmental varnish coating and other details, while retaining the natural texture of logs and maintaining the simple and lightweight shape of furniture, the wear resistance, stain resistance and structural

【Project Summary】

The successful delivery of this 480㎡ warm log-style restaurant furniture customization project in Shenzhen fully confirms Belavit’s professional service capabilities and production strength. As a manufacturer focusing on catering furniture customization, we always take customer needs as the core, and provide customers with worry-free and reliable customized furniture solutions through rigorous material selection, precise space adaptation, strict quality control and efficient full-process communication. In the future, Belavit will continue to adhere to the concept of “quality as the foundation and service as the root”, empowering more catering spaces to create a dining environment that combines aesthetics and practicality.

Project-Related Product